О компании (11)

Children categories

Нашей компании было присвоена звание Алтын сапа

Нашей компании было присвоена звание Алтын сапа

Нашей компании было присвоена звание Алтын сапа

For Partners

We seek for cooperation with strong and honest partners. Dani Nan is always looking for novel ways of development while enjoying sound capacities, a clear structure and everything necessary to produce high-quality Kazakh flour.

If you are interested in working with us as an investor, partner or supplier, we will be happy to meet you and discuss the potential of joint development.

Partner Network

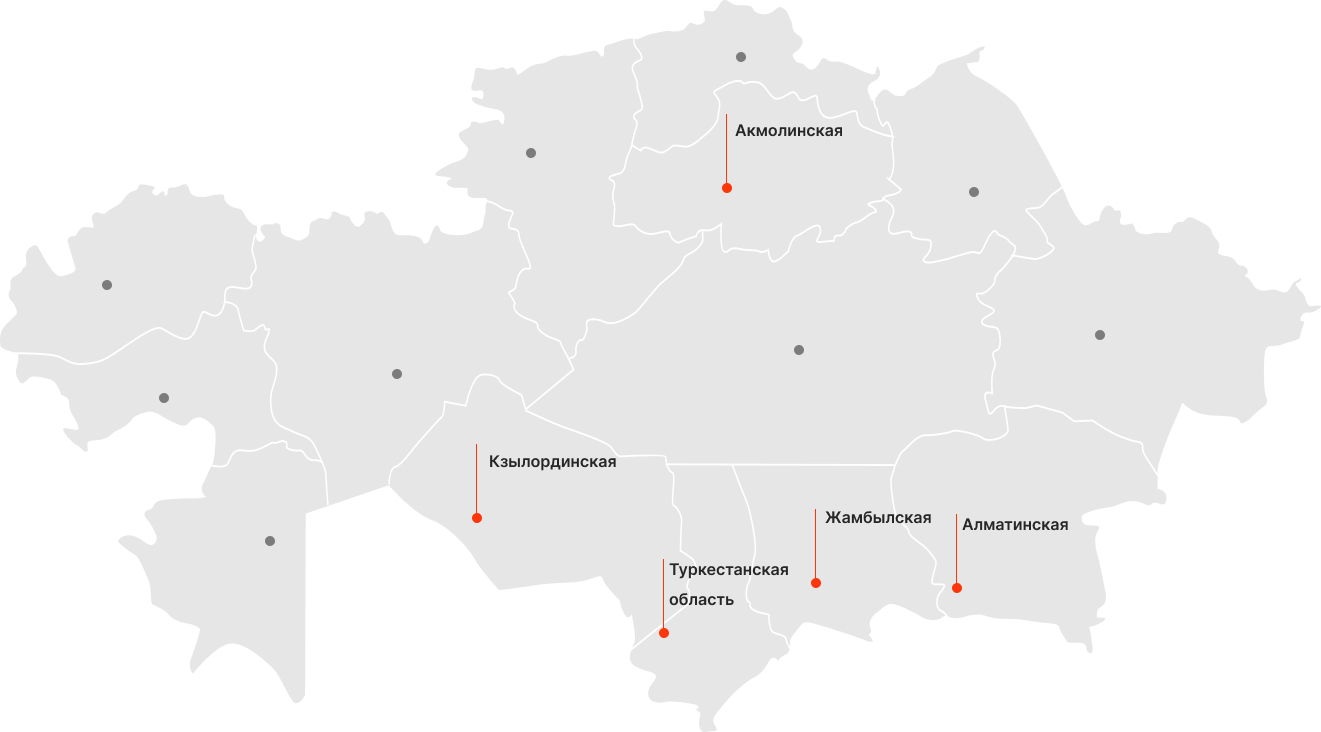

Geography

of cooperation with Dani Nan

- Russia

- Kyrgyzstan

- Uzbekistan

- Azerbaijan

Technology

Dani-Nan company carefully monitors the quality of the product at every stage of its production. For quality control, the company has created a special laboratory and research service equipped with advanced technologies and equipment that allows us to evaluate and control the properties and characteristics of each product at all stages – from the purchase of wheat to the receipt of final products on the shelves of retail stores.

High quality products

No GMOs

Own laboratory

Automated production

Stage 1

- Grain reception

- • Technology for monitoring the state of grain after transportation

- • Verification for the absence of infections, dampness

Stage 2

- Grain selection

- • Optical sorting technology

- • Only the grain that matches our standards sent to the milling machine

Stage 3

- Milling

- • Before starting the processing, the grain is examined for several parameters: colour, smell, nature, gluten, proteins.

Stage 4

- Laboratory

- The quality of flour is confirmed by experienced technological experts in our own laboratory. The control of received raw materials is carried out on high-precision modern equipment that provides a comprehensive profile about the properties of flour and its baking qualities.

The main task of our high-tech laboratory is to carry out control at every stage of production. Receipt inspection of raw materials, examination of intermediate and finished products - allows to provide future consumers with a high-quality flour.

Stage 5

- Packaging, storage

- • Flour is packed in advanced weighing machines.

- • Protection of flour from caking and oxidation is ensured

The next important parameter of the quality of raw materials is the amount of damaged starch. The degree of starch damage determines the water absorption capacity of flour and, accordingly, affects the taste and appearance of future bakery food and other flour products. The optimal level of this parameter is controlled on fully automatic equipment made in France.

Determination of the falling-number that indicates the activity of alpha-amylase enzymes in grain and flour, is carried out on high-precision Swedish equipment. The lower the activity of alpha-amylase, the higher the quality of wheat. The alpha-amylase enzyme is activated during the germination of the grain, destroying the starch. Flour with increased alpha-amylase activity is stored less, and baked products are less airy and dry.

Right now we look for

Want to work with us, but have not found a position that fits you?

Write about yourself to This email address is being protected from spambots. You need JavaScript enabled to view it.

Mission

Dani Nan holding company is created to produce, distribute and sell the best quality product using natural ingredients. In addition, our goal is to promote business practices that support sustainable farming.

The most important point of the company's mission is to meet the needs of stakeholders. Besides company’s management, stakeholders are consumers, employees, investors, suppliers, and governmental organizations. We believe that sustainable growth is hardly achievable without considering different needs of all stakeholders.

- Employees have clear and achievable goals, which, together with the division of responsibilities, leads to increased productivity. The improvement of the company's financial performance is directly reflected in the incentive system and motivation of employees since the business cannot grow without committing to their interests.

- We do guarantee the highest quality products to consumers both in the domestic market and abroad.

- We work closely with governmental organizations and participate in various market development initiatives, providing expert advice on trade issues with foreign countries.

-

1996 – Opening of the bakery.

In hard times of a short supply, we were one of the two largest bakeries in the city (10 tons of flour were used daily).2000 – Launch of the first mill with a processing capacity of 130 tons of grain per day.

-

2005 – Launch of own elevator with a storage capacity of 24,000 tons of grain The launch of own elevator allowed the company to have large grain reserves, preventing the risks of a shortage of raw materials, and, accordingly, stopping production.

2006 – Winning a prize in the Nomination of the contest "The best product of the South Kazakhstan region", held by the akim of the region.

-

2008 – Presentation of products to the first President of the Republic of Kazakhstan during the meeting of the Elbasy with entrepreneurs of Shymkent.

2009 – Winning the "Choice of the Year" contest. The contest determines the leaders of the market of goods and services in Kazakhstan.

2010 – Launch of the second mill with a processing capacity of 300 tons of grain per day. The growing popularity of the brand required an increase in the production of goods to meet the needs of all customers.

-

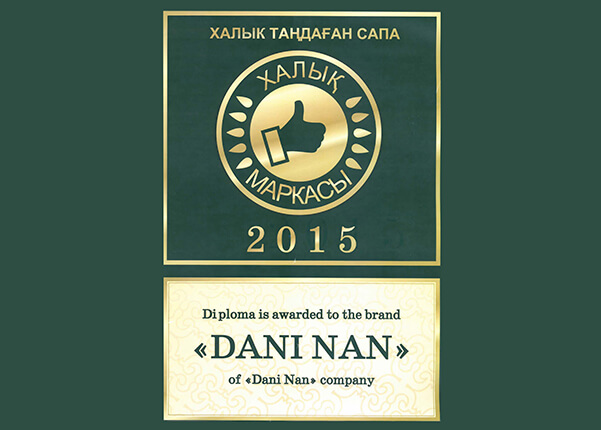

2015 – Dani-nan LLP took part in the national contest of consumer recognition "Halyk Markasy". According to the results of the contest, the largest number of votes were given to the Dani-Nan trademark which officially became the winner in the category "Flour products".

2016 –For the first time in its existence, Dani-Nan LLP had passed the processing mark of 1 million tons of grain.

Address:

Republic of Kazakhstan, 160009,

Shymkent, K. Tsetkin str., 5

Sales Dept.

Shymkent +7 701 525 61 11

Almaty +7 701 783 19 08

Office manager

+7 (7252) 44 30 00

This email address is being protected from spambots. You need JavaScript enabled to view it.

Branch

Almaty city, Iliyskiy tract, 617a, 2nd floor

phone: +7 701 989 26 55 – sales department

phone:+7 701 783 19 08 – accounting

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

2 kg Wheat baking flour

Highest grade

Production

100% Kazakhstani grain

- Raw gluten - 31%

- Whiteness - 68 units

- Moisture – 15 %

3 kg Wheat baking flour

Highest grade

5 kg Wheat baking flour

Highest grade

10 kg Wheat baking flour

Highest grade

25 kg Wheat baking flour

Highest grade

50 kg Wheat baking flour

Highest grade

2 kg Wheat baking flour

First grade

Production

100% Kazakhstani grain

- Raw gluten - 34%

- Whiteness - 53 units

- Moisture – 15 %

25 kg Wheat baking flour

First grade

50 kg Wheat baking flour

First grade

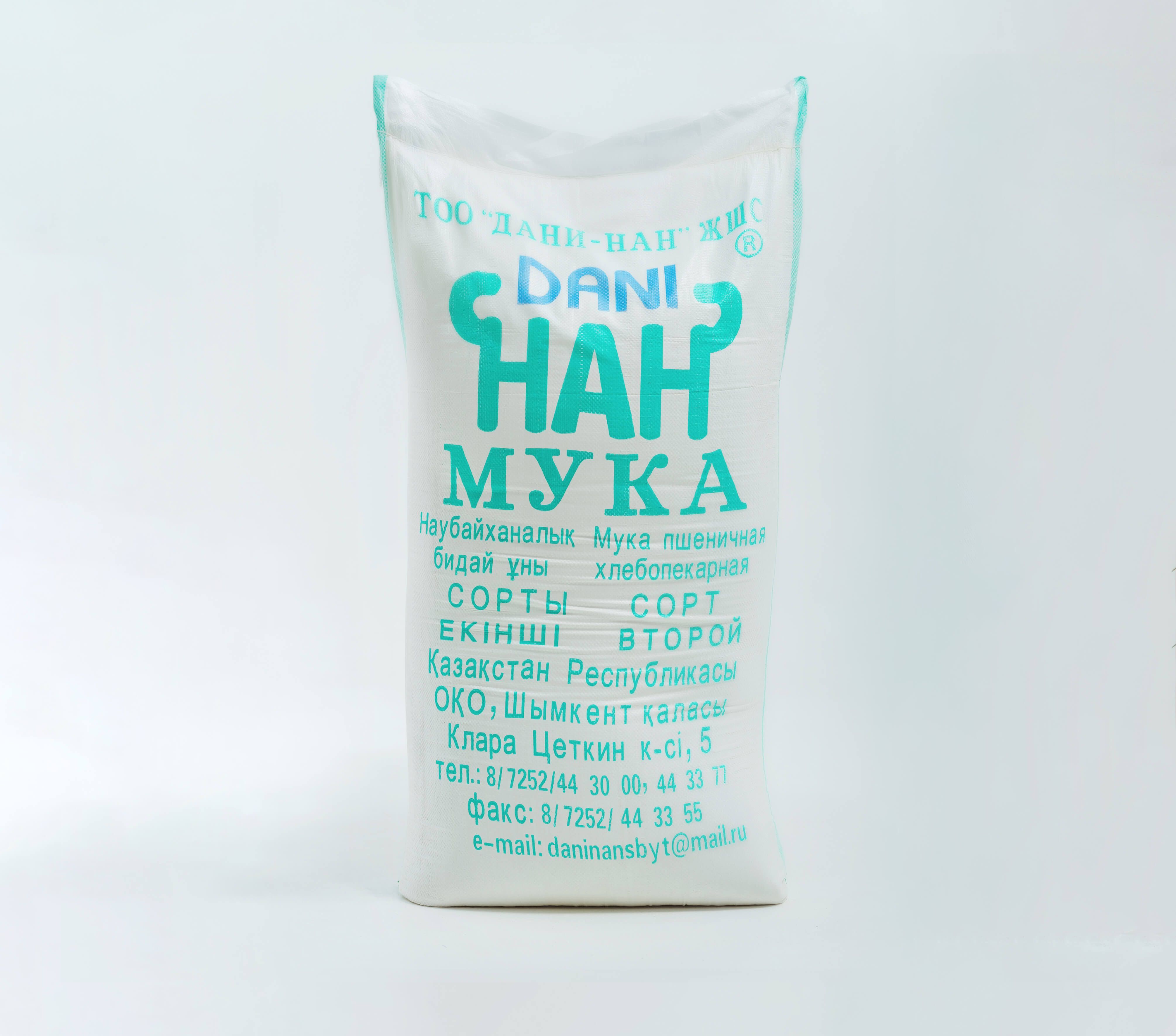

50 kg Wheat baking flour

Second grade

Production

100% Kazakhstani grain

- Raw gluten - 30%

- Whiteness - 32 units

- Moisture – 15 %

More...

Holding

Dani Nan Holding Company is an example of stability and continuous growth. For 25 years of its existence, the production of flour has never stopped. This does not mean that we have not experienced difficulties along the journey. But does mean that reputation is the most important value for us.

We build our relationships with investors, partners, suppliers and employees in such way that these relationships are mutually beneficial and lead to creation and growth.